- Tel:

- 86-577-65163388

- Mobile:

- 13758751196

- E-mail:

- info@raxysj.com

- Address:

- No.577, East three road ,Nanbin Street, Rui'an,Wenzhou,Zhejiang, China

Machine details

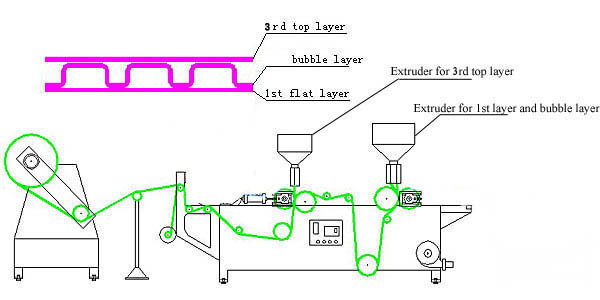

PE Bubble Film (also called polyethylene bubble film) which is divided into ordinary PE bubble film machine and composite polyethylene cushion film crew, is a kind of packaging materials commonly used at present, not only has the shock absorption, impact resistance, heat resistance and good, has the advantages of corrosion resistance, transparency and good, widely used in household, postal parcels precision instrument, bicycle, polyurethane furniture and other packaging. Because the middle layer filled with air cushion film, so the body is light, transparent, flexible, noise, vibration, wear properties, can be made of bubble bag, bubble bag, Kraft paper envelopes car sun block, heat insulation cushion, heat insulation material etc... Adding different additives in plastic material can also create a variety of special anti-static air cushion film. Anti-static air cushion film, used for packaging electronic components, components, such as board, card, to prevent static electricity can play a buffer role.

The characteristics of the machine:

1. With the earthquake and strong reliability.

2. Applicable to a variety of different materials, including low density polyethylene (LDPE), linear low density polyethylene (LLDPE).

3. Can produce a variety of bubble size and various films, 6mm, 8mm, 10mm, 20mm, 25mm...And by changing the bubble.

4. Can be customized to composite film, foam PE film, aluminized paper.

One time forming - products, production of high speed and high efficiency, good quality of products.

Adopt frequency conversion control, speed control of high precision, wide range, low energy consumption, reliable operation.

Adopt infrared energy-saving heater intelligent digital display temperature control, automatic temperature controller, high efficiency and low consumption.

Optional configuration of automatic feeding, quick change filter, and electric automatic flip closed

|

Main Technical Variables |

||||||

|

Model |

XYPEG- |

XYPEG- |

XYPEG- |

XYPEG- |

XYPEG- |

XYPEG- |

|

Screw diameter |

65/60 |

80/65 |

85/70 |

90/75 |

105/90/90 |

110/100/100 |

|

Film width |

1200mm |

1500mm |

1800mm |

2000mm |

2500mm |

3000mm |

|

Max output |

70kg/h |

90kg/h |

100kg/h |

110kg/h |

150kg/h |

200kg/h |

|

Total power |

82kw |

110kw |

120kw |

140kw |

200kw |

230kw |

|

Screw L/D |

30:1 |

30:1 |

30:1 |

30:1 |

30:1 |

30:1 |